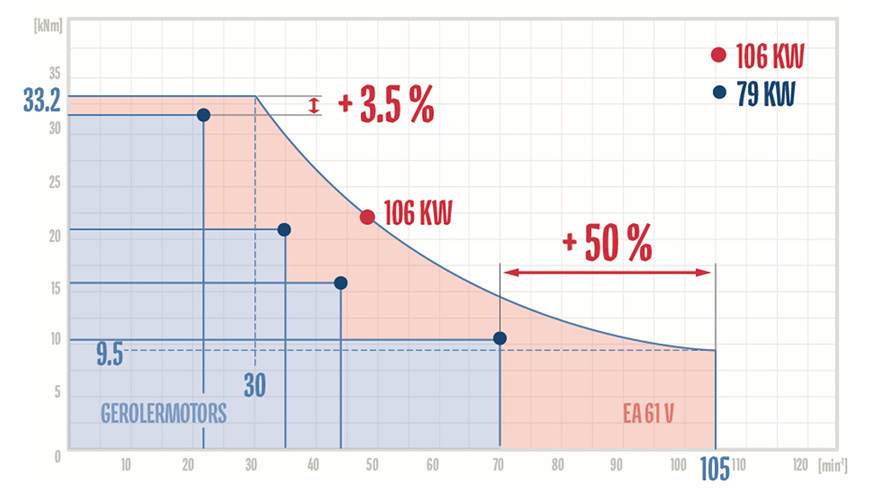

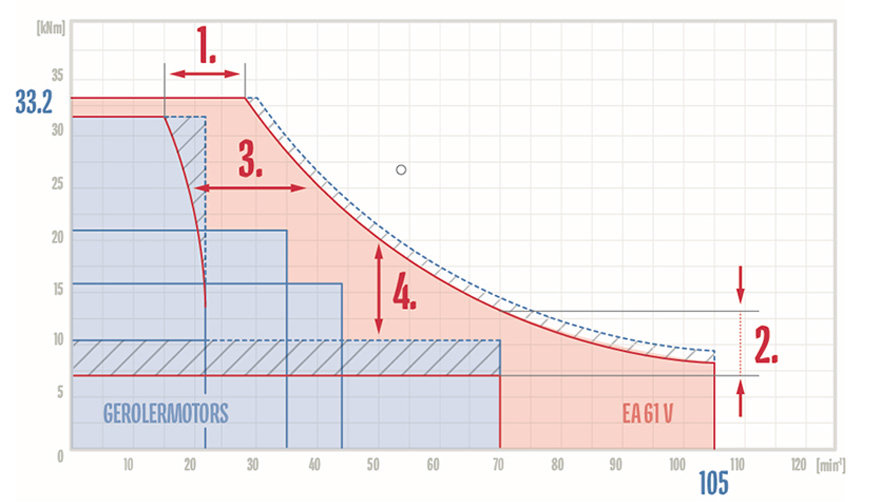

Diagram 2

Geroler motors versus EA 61 V – (Real-life) comparison with the RH 32 X, actual values

So much for the theory - in real-life conditions, the advantages of this new drive system compared to Geroler motors are even more pronounced, as can be seen in diagram 2:

1. Speed stability at the highest level of torque

Thanks to the significantly better volumetric efficiency of the axial piston motor, there is markedly less speed loss at the highest level of torque.

2. Higher practical torque at high speed

Due to the higher efficiency rate of the EA 61 V and the fact that serial shifting is no longer required, the losses in top gear are significantly smaller.

3. Higher speed at the same torque

Where torque of 25 kNm is required, the speed available almost doubles e.g. 38 rpm instead of 20 rpm

4. Higher torque at the same speed

At a speed of 50 rpm, roughly 3 times the practical torque is available e.g. approx. 20 kNm instead of 7 kNm.

Savings potential

Due to the significantly greater efficiency (see points 1 and 2 diagram 2 above) and the greater net drilling capacity (see points 3 and 4 diagram 2 above), markedly lower drive performance is required for the EA 61 V drive system, thereby saving on fuel. By way of an example to illustrate the savings potential, EURODRILL is assuming average savings of 10 kW/h on drive performance - and this is a conservative estimate. As approx. 0.2 l of diesel is saved for each kW/h not required, a saving of some 20,000 liters of fuel is achieved over 10,000 operating hours.

An incredible 53 tonnes of CO2 is saved as a result, which makes a huge contribution towards reducing the carbon footprint on the construction site.

Even with higher acquisition costs the new system remains an attractive proposition, because with the documented savings payback is rapid - and at the same time, deploying the EA 61 V drive system allows the drilling rig to be operated at a higher drilling speed. The lower output required means important drilling rig components (motor, pumps and other hydraulic components) are conserved for longer. The thermal economy of the entire drilling rig is significantly improved.

The EA 61 V drive system in action

The latest-generation drive system is being deployed, amongst other projects, for one in Antwerp. In 2024, not far from the city center, 350 m of new quay walling is to be secured with 150 anchors in total. The building contractor working on this project, Herbosch-Kiere (part of the EIFFAGE Group), had drilled some test anchors in advance, to make the dimensioning of later anchors easier. As the existing hydraulic hammer was not equal to the challenge of a 219 mm diameter and a drilling depth of up to 42 m, the decision was taken to deploy a EURODRILL RH 32 X using EA 61 V drive system. It had to drill through several meters of sand, followed by a thick layer of clay and finally 4 m of the infamous, extremely hard "Boomse Klei". Thanks to its high torque and powerful percussion unit, it was able to master the combination of a large drilling diameter and deep drilling depth to the full satisfaction of client Herbosch-Kiere.

![[Translate to EN:] [Translate to EN:]](/fileadmin/Datenpflege/News/Messe_2022/1.jpg)

![[Translate to EN:] [Translate to EN:]](/fileadmin/Datenpflege/News/Messe_2022/2.jpg)

![[Translate to EN:] [Translate to EN:]](/fileadmin/Datenpflege/News/Messe_2022/3.jpg)

![[Translate to EN:] [Translate to EN:]](/fileadmin/Datenpflege/News/Messe_2022/4.jpg)

![[Translate to EN:] [Translate to EN:]](/fileadmin/Datenpflege/News/Messe_2022/5.jpg)

![[Translate to EN:] [Translate to EN:]](/fileadmin/Datenpflege/News/Messe_2022/6.jpg)

![[Translate to EN:] [Translate to EN:]](/fileadmin/Datenpflege/News/Messe_2022/7.jpg)

![[Translate to EN:] [Translate to EN:]](/fileadmin/Datenpflege/News/Messe_2022/8.jpg)

![[Translate to EN:] [Translate to EN:]](/fileadmin/Datenpflege/News/Messe_2022/9.jpg)

![[Translate to EN:] [Translate to EN:]](/fileadmin/Datenpflege/News/Messe_2022/10.jpg)

![[Translate to EN:] [Translate to EN:]](/fileadmin/Datenpflege/News/Messe_2022/11.jpg)

![[Translate to EN:] [Translate to EN:]](/fileadmin/Datenpflege/News/Messe_2022/12.jpg)

![[Translate to EN:] [Translate to EN:]](/fileadmin/Datenpflege/News/Messe_2022/13.jpg)

![[Translate to EN:] [Translate to EN:]](/fileadmin/Datenpflege/News/Messe_2022/14.jpg)

![[Translate to EN:] [Translate to EN:]](/fileadmin/Datenpflege/News/Messe_2022/15.jpg)

![[Translate to EN:] [Translate to EN:]](/fileadmin/Datenpflege/News/Messe_2022/16.jpg)